- Home

- Sustainability Home

- Environment

Circulating Natural Resources and Preventing Pollution

- Sustainability Home

-

JINS’ Ideal World

-

Material Issues and Medium to Long-Term Goals

-

Messages from Executives

- Sustainability Promotion System

-

Environment

-

Society

-

Contributing to Local Communities

-

Governance

- External Evaluation and Initiatives

Policy on Circulation of Natural Resources and Prevention of Pollution

JINS is committed to resource recycling, reduction and proper management of hazardous waste, and prevention of pollution toward realizing a recycling-oriented society. As an eyewear manufacturer that uses a large volume of plastic in its products, we also consider it necessary for us to lead the industry in making the switch to plastic-free and sustainable materials. We are making progress on shifting to zero waste products and 100% recyclable eyewear as part of our 2050 Goal to realize resource recycling across the entire supply chain, from procurement of raw materials to production, distribution, sales, and disposal/collection. Moreover, we have set the ratio of eyewear (resin products) made from sustainable materials as a 2030 Goal. We will further conserve resources by researching and developing sustainable eyewear, switching materials, and reducing waste wherever possible. As waste and water resources are also important global issues, we will strengthen measures to minimize risks in our business operations through consistent and thorough management throughout the entire supply chain. Specifically, JINS, which employs a SPA model for integrating product planning, production, and sales, continuously monitors and provides guidance for improvement to suppliers it contracts to manufacture eyewear, along with working with suppliers to reduce their environmental impact. In our business activities, we will strive to reduce and properly dispose of hazardous chemical substances and pollutants. We will also work to prevent and reduce pollution by complying with relevant laws and regulations, while proactively making efforts to maintain and conserve the natural environment.

Related Data

Producing Recyclable Eyewear Products

In May 2021, as the first step in our recyclable eyewear initiative for 2050, we launched a new line of classic, highly refined frames made using highly biodegradable bioplastic material as part of our sunglasses brand “JINS & SUN.” These products are made from M49, a plant-based bioplastic that is more highly biodegradable by microorganisms than ordinary plastics. M49 was developed by long-established Italian eyewear materials manufacturer Mazzucchelli, which is popular all over the world for producing high quality and beautiful materials. It is a high-quality material that is not only environmentally friendly, but also aesthetically pleasing with a beautiful luster, transparency, pleasant touch, and smooth surface. Blending environmental considerations with quality, we have also set prices that are affordable for customers of all ages. To ensure that our products will be loved by customers over many years, we have adopted a special structure that can be maintained and used for a long time, along with a classic and timeless design.

As the sixth product line of the “JINS Design Project,” we developed the “HILO JINS × Patricia Urquiola” eyeglasses in collaboration with Patricia Urquiola, a Milan-based designer who works internationally. The product has been designed with a focus on sustainability, based on the concept of “HILO” (meaning “thread” in Spanish). After undergoing over a year of practical application testing, Arkema’s Rilsan® Clear G850 Rnew®, which contains castor oil obtained from castor oil seeds, a non-edible crop, was used as the material. We have managed to perfect the balance between aesthetics and strength, which has been an issue for sustainable products, with a collection that combines Urquiola’s signature beautiful colors with durability and flexibility.

Long-Lasting Quality and Design

To reduce environmental impact, it is necessary to extend the life cycles of our products (product lifespans). JINS has collaborated with world-class designers in its aim to create universal and timeless designs that will be loved by customers over a long time. In addition to frames that offer both long-term comfort when wearing and long-lasting quality, JINS offers a wide range of high-quality and high performance lenses. Along with providing suitable eye examinations at the time of purchase, we also offer maintenance services after purchase. Through these activities, we are using less raw materials in production, thereby contributing to reducing our environmental impact.

Green Bond Investment in JEPLAN, Inc.

Since its establishment in 2007, JEPLAN, INC. has been working to realize a circular society through activities that connect together companies and consumers who want to recycle, the development and manufacture of recycled fibers, and consulting on recycling. JINS HOLDINGS participated in the PLA-PLUS Project for recycling plastic from products, which is run by JEPLAN, INC. in cooperation with the Ministry of the Environment, in 2012. We are currently working on activities to collect plastic eyewear no longer needed by customers and recycle them into fuel through JEPLAN’s BRING PLA-PLUS project. In January 2020, we acquired common stock of JEPLAN, INC. via a partial capital increase through third-party share issuance. We have taken this opportunity to promote eyewear recycling activities.

Click here for details on JEPLAN, INC.

Collection and Recycling Initiatives

Collecting and Recycling Glasses That Are No Longer Needed

BRING PLA-PLUS

As the company with the highest sales volume for eyewear in Japan, JINS is working to recycle eyewear. From 2012, we have been working on activities to collect plastic eyewear no longer needed by customers and recycle them into fuel through the BRING PLA-PLUS project for recycling plastic from products run by JEPLAN, INC. Moreover, we formed a capital alliance with JEPLAN, INC. in 2020. From now on, we will further leverage the technological capabilities and knowledge of both companies to promote sustainability in eyewear by working toward producing recyclable eyewear.

Recycling Eyeglasses

-

Please bring us your no longer needed eyeglasses

-

Crushed eyeglasses are transported to a BRING PLA-PLUS project partner factory.

-

They are recycled into energy and other new resources such as gas and coke (some of which are used for experiments into new technologies).

FAQ

-

Where can I donate my eyeglasses?

Eyeglasses can be donated at JINS stores nationwide and rim of jins.

-

How can I donate my eyeglasses?

Please ask a JINS staff to take you to the BRING PLA-PLUS project eyeglasses recycling box located in each JINS store where you can put your no longer needed eyeglasses or sunglasses (*the box is located in different places in each store).

-

Can any kinds of eyeglasses be donated?

Thanks to advanced Japanese technology, both frames and lenses are 100% recyclable. All eyewear products can be donated, regardless of the type of frame material or lens type (i.e., plastic/metal frames, eyeglass lenses/sunglasses, etc. (non-JINS eyewear can also be donated).

Initiatives Reducing Waste

Reducing Waste by Introducing an AI-Based Predictive Management System

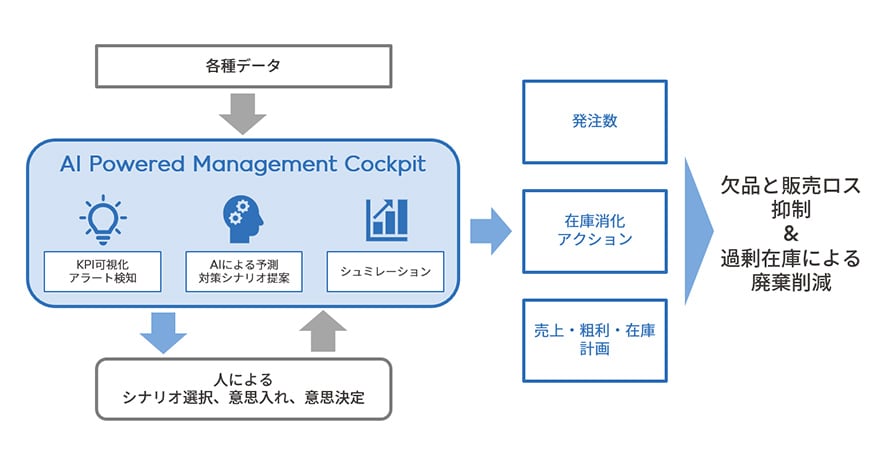

In order to reduce product shortages and waste due to excessive inventory, we have been using a predictive management system that uses the AI Powered Management Cockpit, a solution for supporting management decisions through AI provided by Accenture Japan Ltd, since February 2022. In the trial operation carried over one year, it was confirmed that sales loss (missed sales) due to product shortages was reduced by approximately 65% (gross profit basis; compared to 2019) and loss from waste was reduced by approximately 10% (including loss from disposal and revaluation; compared to 2019). (*Results of comparisons with past results. These are based on the overall effect, not simply the measures in question.) Through trial operations, we established a customized proprietary system that combines AI and human empirical rules and also reflects verification results. We are working to improve the accuracy of the system with a view to utilizing it in future overseas operations.

Other Resource Recycling Initiatives

Shifting to Recycled Paper Shopping Bags

Previously, JINS was using shopping bags that were as environmentally friendly as possible and had obtained a total of seven environmental certifications. However, in order that shopping bags are used only by customers who need them and to make effective use of resources, all stores have started charging for bags (with some exceptions). Furthermore, revenue from shopping bags is used for the “More Outdoor Play Project” as an initiative for giving back by creating a sustainable society.

Adopting Environmentally Friendly Store Fixtures

Adopting environmentally friendly store fixtures

Shifting to Eco-Friendly Eyeglass Cleaning Cloths

JINS has been gradually switching to the use of eco-friendly materials in its eyeglass cleaning cloths, which are provided free of charge to customers alongside their purchase, starting in August 2022. The previous cloths were made from 100% petroleum-derived raw materials, however our new eco-friendly cloths maintain superior cleaning performance while at the same time using approximately 60% recycled fibers made from clean plastic bottles collected and sorted by local governments and stores in Japan. Moreover, the eco-friendly cloths are not dyed, but are made of undyed material left in their original color.

Store Staff Uniforms Made of Recycled Materials

In July 2022, JINS updated the uniforms of store staff, adopting uniforms made of recyclable materials at all stores across Japan. For the spring/summer shirts, original fabrics that are comfortable to wear and wrinkle-resistant while also having excellent water absorbency and quick-drying properties were created by blending threads made from chemically recycled used plastic bottles for the warp with regular water absorbent and quick-drying polyester threads for the weft. Through this, while the material used is 100% polyester, 54% is recycled material, achieving both functionality and environmental friendliness. Uniforms that are no longer worn are separated into materials and parts to be reused as recycled polyester and automobile interior materials, along with the coke oven chemical feedstock recycling of plastics. Also, all old uniforms are being collected and recycled, and efforts will be made to thoroughly recycle natural resources.

- Sustainability Home

-

JINS’ Ideal World

-

Material Issues and Medium to Long-Term Goals

-

Messages from Executives

- Sustainability Promotion System

-

Environment

-

Society

-

Contributing to Local Communities

-

Governance

- External Evaluation and Initiatives